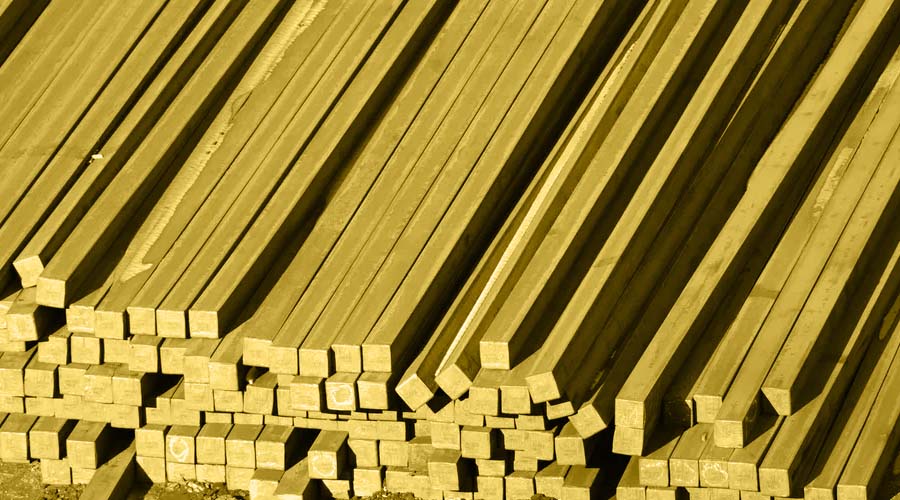

A billet is a semi-finished product used in the metalworking and manufacturing industries. It is typically a solid, rectangular or square-shaped piece of metal that has been processed to a specific size and shape. Billets are used as the raw material for producing various finished metal products through further processing techniques such as rolling, forging, or extrusion.

Characteristics:

Production Process:

Applications:

Advantages:

Standards and Specifications: Billets are often produced according to industry standards which ensure consistency in quality and performance. Examples of standards include ASTM, ISO, and EN specifications, depending on the material and region.

Billets are solid, usually rectangular or square, sections of metal that are used as a raw material in the manufacturing of various products. They are often used in forging, rolling, or extrusion processes. Here’s a summary of billet specifications across different standards:

| Property | Specification |

|---|---|

| ISO Symbol | No specific ISO symbol for billets; depends on the material |

| UNS | Varies by material; for example, C10100 for copper billets |

| EN | Varies by material; for example, EN 10277 for steel billets |

| BS | Varies by material; for example, BS 970 for steel billets |

| JIS | Varies by material; for example, JIS G 3505 for steel billets |

| IS | Varies by material; for example, IS 1875 for steel billets |

1. Steel Billets

| Specification | Description |

|---|---|

| ISO | ISO 4957 (for alloy steels) |

| UNS | Various (e.g., UNS G10400 for carbon steel) |

| EN | EN 10083-2 (carbon steels) |

| BS | BS 970 (steel grades) |

| JIS | JIS G 3505 (carbon steels) |

| IS | IS 1875 (carbon and alloy steels) |

2. Aluminum Billets

| Specification | Description |

|---|---|

| ISO | ISO 209 (aluminum and aluminum alloys) |

| UNS | UNS A92024 (for aluminum alloys) |

| EN | EN 573-3 (aluminum alloys) |

| BS | BS EN 573-3 (aluminum alloys) |

| JIS | JIS H 4000 (aluminum and aluminum alloys) |

| IS | IS 733 (aluminum alloys) |

3. Copper Billets

| Specification | Description |

|---|---|

| ISO | ISO 7153-1 (copper and copper alloys) |

| UNS | UNS C10100 (for high-purity copper) |

| EN | EN 1977 (copper and copper alloys) |

| BS | BS 2872 (copper alloys) |

| JIS | JIS H 3300 (copper and copper alloys) |

| IS | IS 191 (copper and copper alloys) |

These tables provide an overview of how billet specifications can vary by material and standard. Each standard offers specific guidelines and requirements for the composition, dimensions, and properties of billets used in various industrial applications.

Overall, billets play a crucial role in the metal supply chain, serving as the foundational material for a wide range of industrial applications.