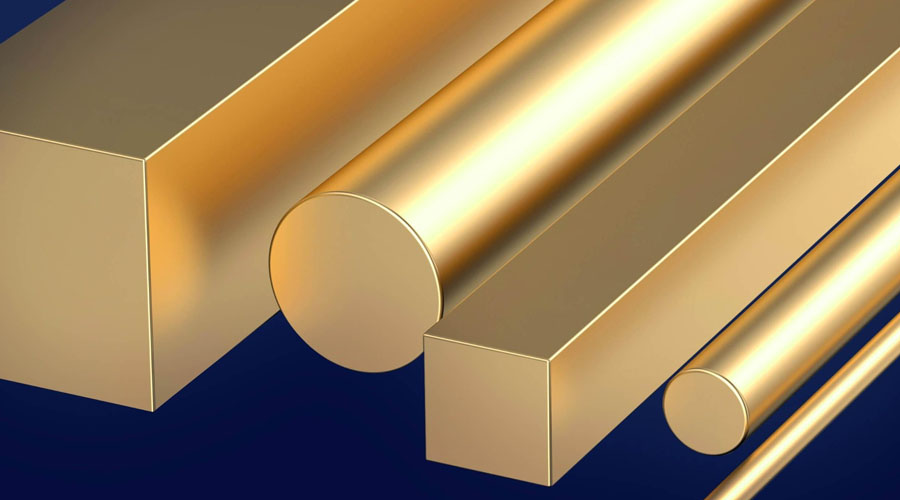

Aluminium bronze is a high-strength, corrosion-resistant copper alloy characterized by its distinctive golden color and excellent mechanical properties. It primarily comprises copper, with aluminium as the main alloying element, usually combined with other metals like iron or nickel to enhance specific traits. This alloy is valued for its robustness in harsh environments, including seawater and chemical exposure.

Standards and Specifications:

Properties and Applications:

Aluminium bronze alloys typically have high tensile strength, excellent resistance to wear and corrosion, and good machinability. These properties make them ideal for marine hardware, pumps, valves, and other high-stress components.

Chemical Composition (Typical)

| Element | % Range |

|---|---|

| Cu | 85-90% |

| Al | 6-12% |

| Fe | 2-4% |

| Ni | 0-5% |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 550-800 MPa |

| Hardness | 150-250 HB |

| Elongation | 2-10% |

Aluminium bronze's unique properties and standards make it a crucial material in various demanding applications.